HAFA Industrial Lubricants

The industrial sector is constantly developing to meet the optimisation needs of energy expenses and achieve optimised productivity. Choosing high-performance, adapted lubricants helps respond to these expectations while improving the performance and lifespan of industrial equipment such as machines, industrial vehicles, tools and production systems. They reduce maintenance costs by extending the lifespan of equipment and minimising production shutdowns. They also reduce equipment failure and overheating risks, thereby decreasing the risk of accidents.

Our industrial lubricants are placed in several different categories: mineral oil, synthetic oil and industrial grease. Each one is formulated to meet specific needs. Contact our teams to ask for a recommendation and find the lubricant that responds to your industrial applications.

GENERAL MAINTENANCE

The industrial lubricants dedicated to general maintenance are specific products designed for maintenance applications in the industrial sector.

An adapted lubricant improves equipment performance and durability.

More than just about keeping production equipment in good condition, industrial maintenance is a major factor in improving the quality of production management for companies. Our technical teams made up of sales representatives, product application managers and chemists are there to support you every day in the field and advise you on implementing solutions adapted to your manufacturing processes.

Our wide product range makes us the best supplier for all of your lubrication needs, whether they be for hydraulic systems, gearing, bearings, reducers, compressors or pneumatic equipment.

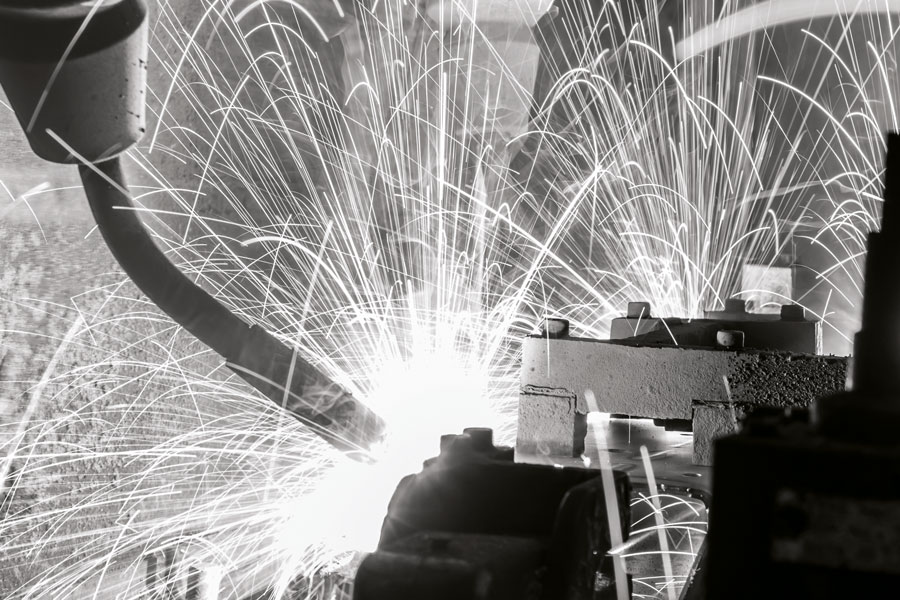

METAL PROCESSING

The fluids dedicated to metal processing are an integral part of the manufacturing process. They provide lubrication to ensure optimised machining performance and protection against equipment wear. They reduce the heat and friction between cutting tools and machined pieces while preventing grinding burns and smoke development. They improve the quality of the machined pieces by continuously clearing off accumulated metal filings, shavings and small particles from the tools and the surface of the piece. It is therefore essential to use high-quality, adapted lubricants to extend the lifespan of your tools, improve working conditions and protect the health of equipment operators.

CATALOG BEING UPDATED

AGRI-FOOD

The agri-food industry needs specially designed products for its applications. These specific lubricants are used to lubricate production, transformation and packaging equipment. The lubricants for the agri-food sector are subject to strict regulations to guarantee food safety and the quality of finished products. They must also meet all food quality standards. Agri-food industrial lubricants possess technical performance while taking into account the sector’s requirements and constraints. It is extremely important to guarantee consumer safety. To ensure this, our products have earned NSF, Halal and Kosher certification.